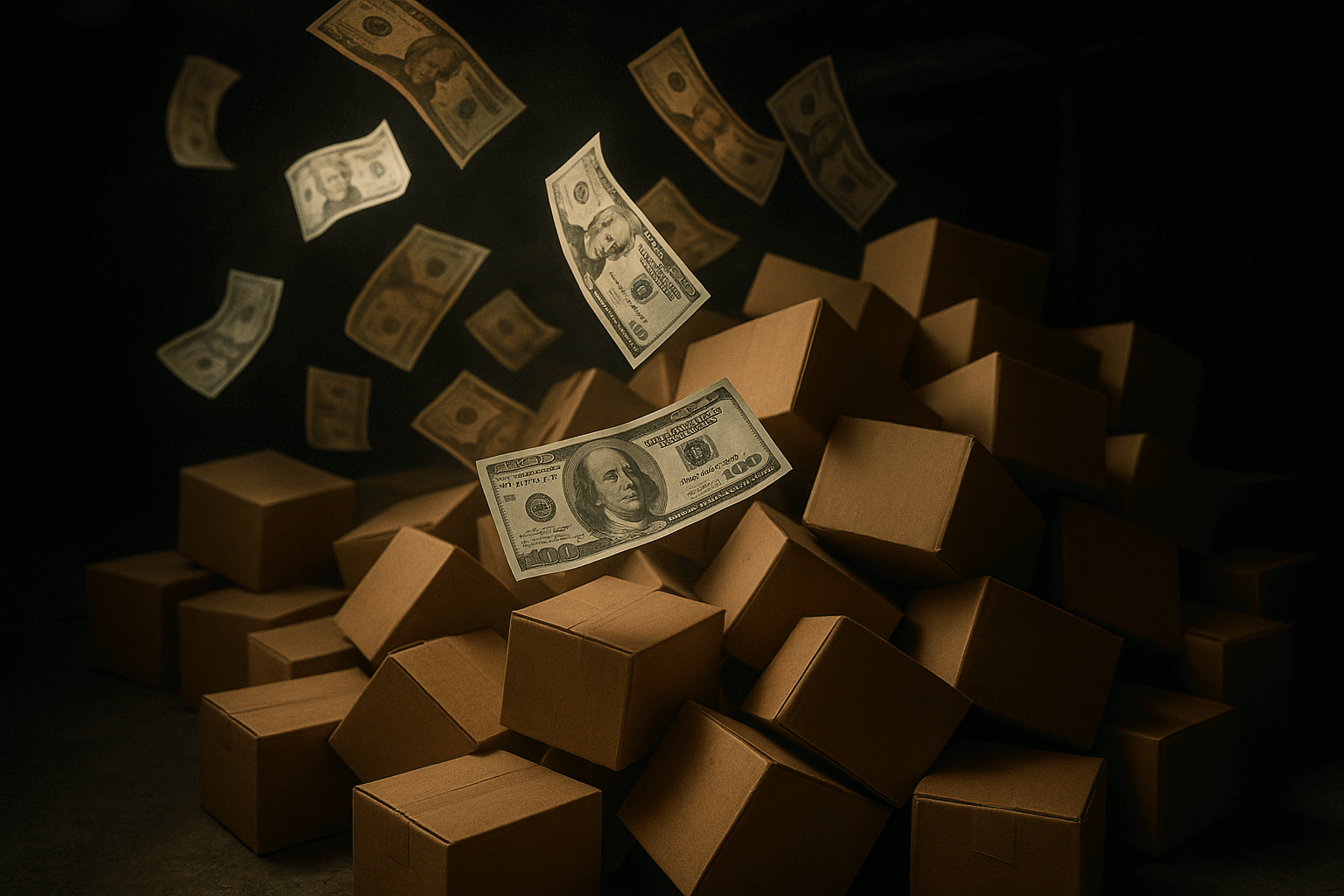

Is your warehouse a source of constant stress? You've mastered the basics of inventory management—perhaps by reading guides on general warehouse management principles — but the problems keep piling up: shipping delays, constant out-of-stocks, and labor costs spiraling out of control. Your team is working hard, but they're trapped in a system that’s holding your business back.

You're not just losing money; you're damaging your reputation with every mis-picked order.

This isn't another high-level guide. This is a problem-solving manual for business owners who know they need a change. We'll dissect the real costs of manual processes, provide a framework for calculating your potential return on investment, and show you a step-by-step path to implementing software automation that delivers tangible growth.

The True Cost of Manual Warehouse Operations

The most dangerous costs are the ones you don't track. A misplaced item seems minor, but these issues compound into significant financial drains. As industry research shows, these are not just operational hiccups; they are critical financial vulnerabilities.

"Common errors, predominantly stemming from manual processes, lack of integrated systems, and insufficient analytics, lead to significant financial losses, reduced operational efficiency, and damaged customer relations."

| Manual Process Flaw | Direct Financial Impact | Hidden Business Impact |

|---|---|---|

| Manual Goods Receiving | Wasted labor hours; Costs of returning incorrect supplies. | Production/sales delays; Inaccurate stock levels from day one. |

| "Memory-Based" Put-Away | Time wasted searching for items; Increased risk of inventory damage. | Inefficient use of space; Higher staff training costs; Stock expiry. |

| Paper-Based Picking | High costs of mis-picks (shipping, returns, replacement). | Drastic drop in customer satisfaction; Negative reviews; Loss of repeat business. |

| Periodic Manual Stocktakes | High overtime labor costs; Complete shutdown of warehouse operations. | Massive sales disruption; Instantly outdated data. |

| Lack of Real-Time Data | Cost of rush orders for out-of-stock items; Lost sales. | Inability to make informed purchasing decisions; Damaged supplier relationships. |

If you recognize your business here, it's the sign of a broken system. The solution isn't to work harder; it's to work smarter with the right tools.

The Two Faces of Automation: Physical vs. Software (And Where to Start)

When business owners hear "warehouse automation," they often picture multi-million dollar robots. While physical automation is transformative, the most impactful and accessible starting point for SMBs is software automation, driven by a Warehouse Management System (WMS). It acts as the central brain of your warehouse, optimizing every process without the need for a single robot. For growing businesses, this is the logical first step.

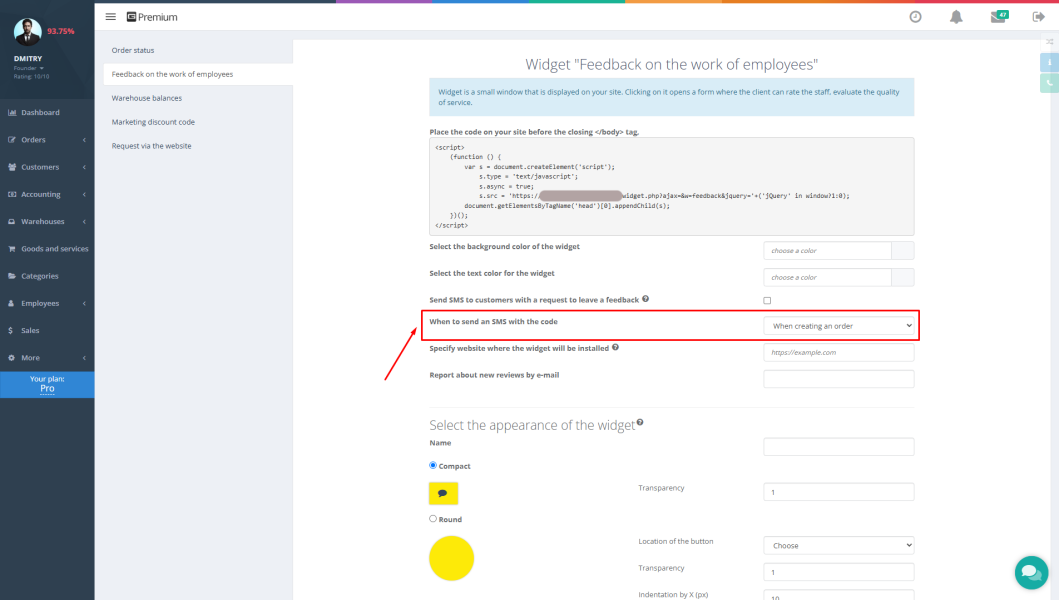

How a WMS Automates Your Critical Warehouse Processes

Here’s how a modern WMS transforms your daily operations from manual chaos into automated efficiency.

1. Goods Receiving: Perfect Inventory from the Start

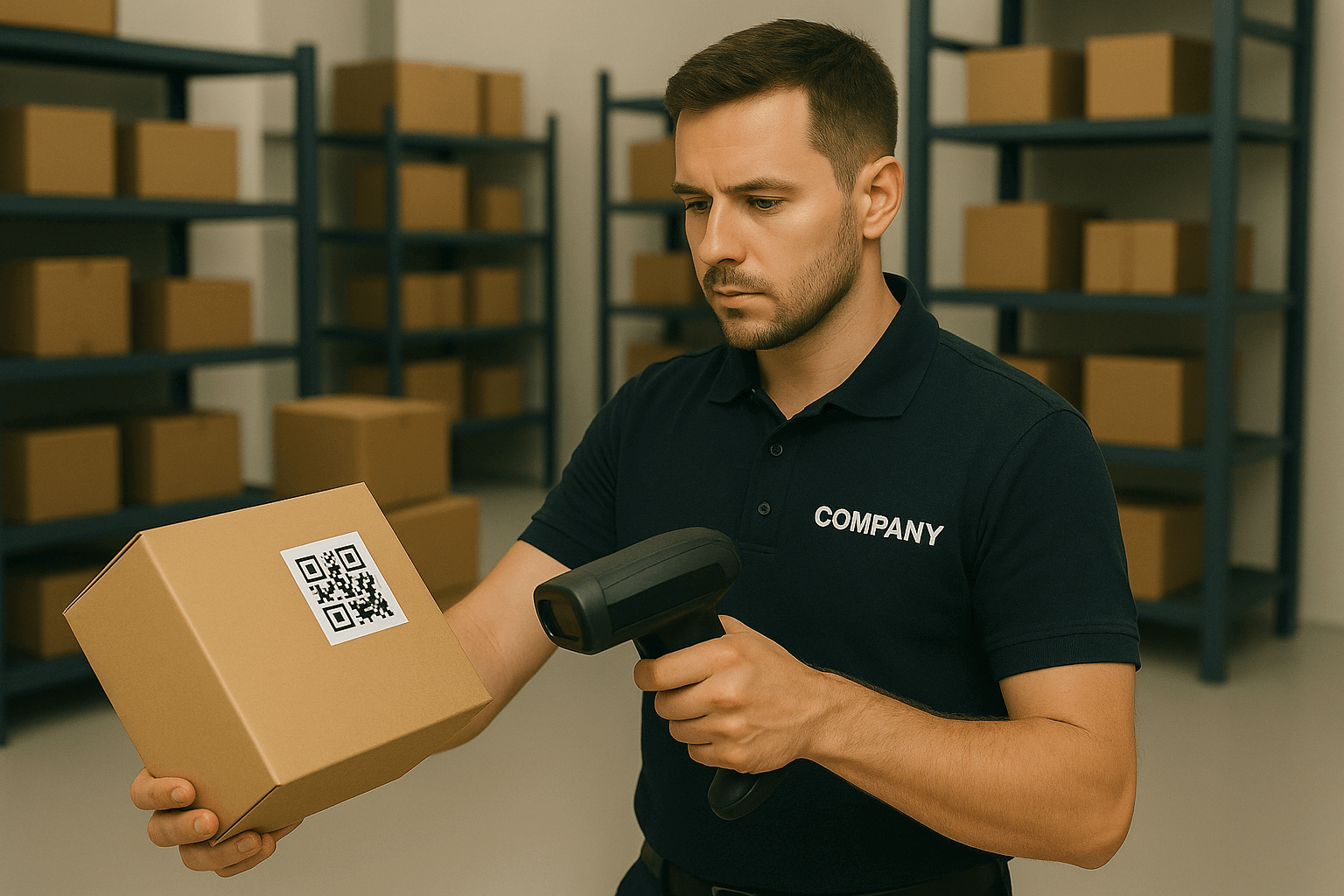

A barcode scanner instantly verifies items against the purchase order. Any discrepancy is flagged on the spot, not weeks later during a customer complaint.

2. Put-Away: The End of "Where Did I Put It?"

An address-based storage system eliminates guesswork. The WMS directs employees to the precise, optimal location (e.g., Aisle A, Rack 03, Shelf 2), ensuring every item is tracked and easy to find.

3. Picking & Packing: Speed, Accuracy, and Happy Customers

The WMS generates an optimized picking route, guiding your picker from one location to the next. Scanning each item before it goes into the cart ensures 99.9%+ accuracy, turning fulfillment into a competitive advantage.

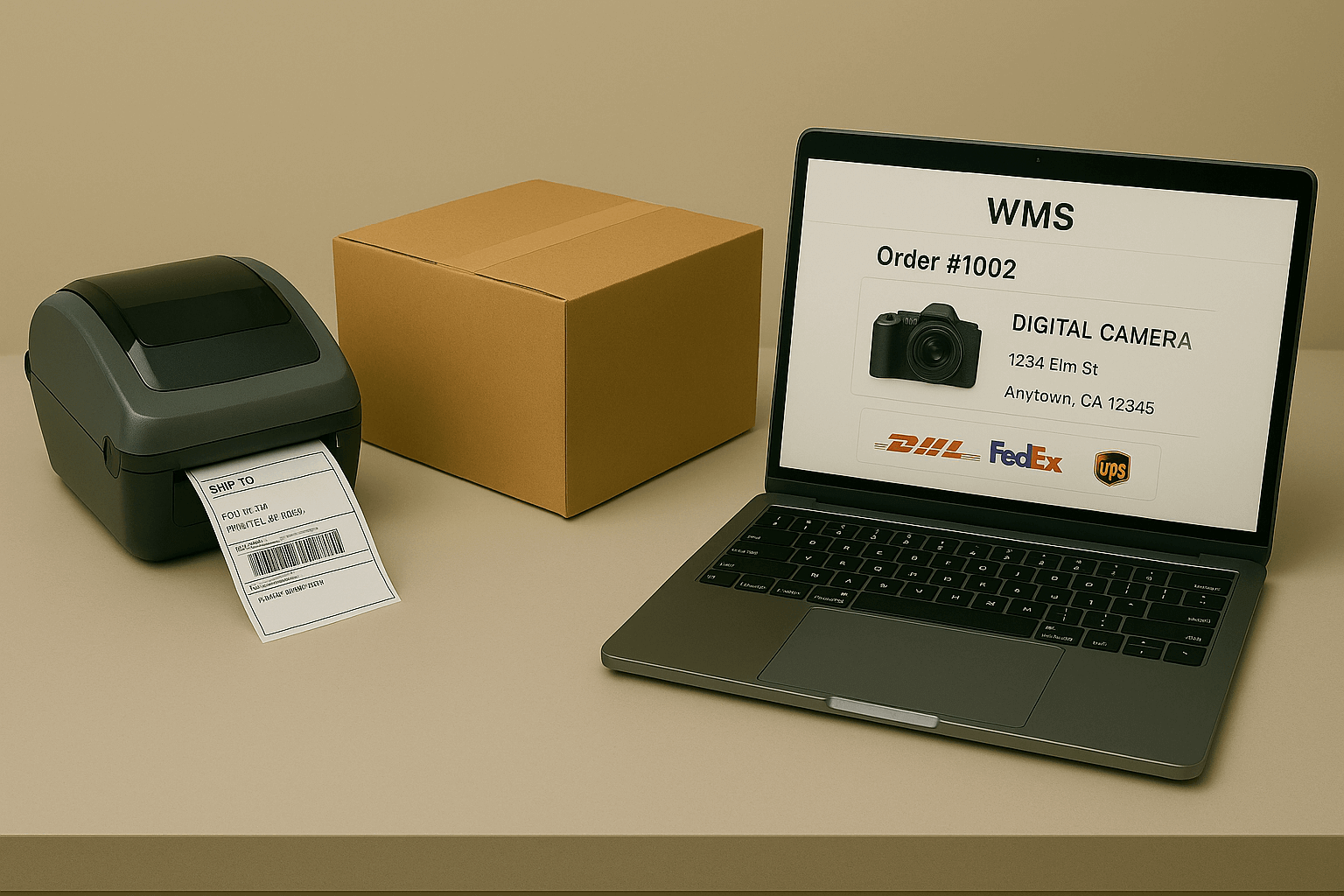

4. Shipping: Integrated and Error-Free

A good WMS integrates directly with shipping carriers. It generates labels with verified addresses in one click and sends automated tracking information to customers, reducing "Where's my order?" inquiries.

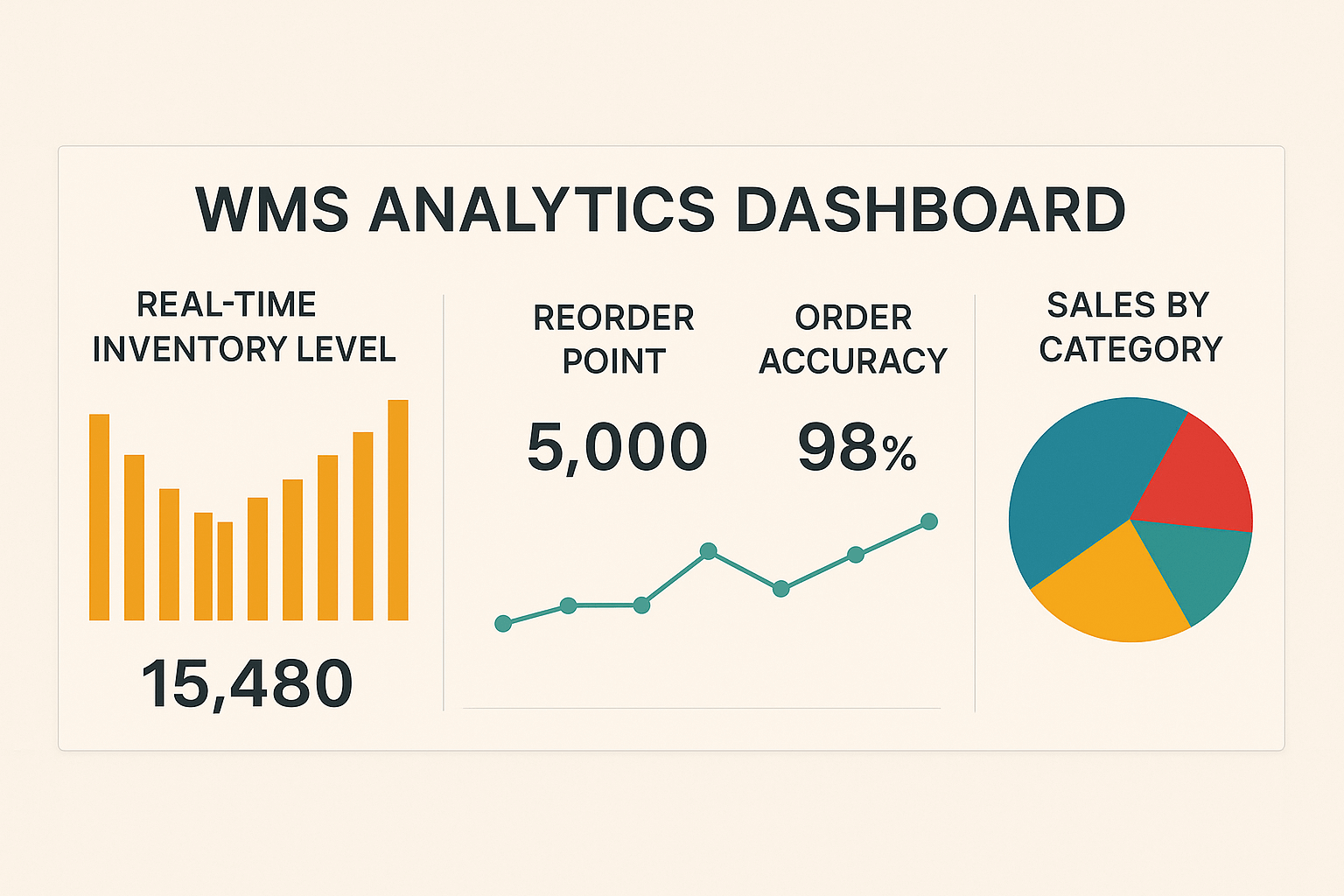

5. Inventory Control: Live Data, Not a Dead Reckoning

Your inventory levels are updated in real-time with every scan. You can perform quick "cycle counts" on specific items with zero operational downtime, ensuring you always have data you can trust.

Case Study: Achieving 99.5% Accuracy

Consider "SpeedFulfill," an online retailer of custom apparel. They faced ballooning costs from picking errors (wrong sizes/colors) and frequent overselling of popular items. Their manual, spreadsheet-based system couldn't keep up.

After implementing a WMS, they saw transformative results within six months:

- Order Picking Errors: Dropped by 99.5%.

- Order Processing Time: Reduced by 40%, from 24 hours to same-day dispatch.

- Inventory Accuracy: Real-time visibility eliminated overselling entirely.

- Customer Satisfaction: CSAT scores increased by 20% due to faster, more accurate deliveries.

This wasn't achieved with robots, but by implementing a core software system that brought order and accuracy to their existing team and warehouse.

Measuring Your Success: Calculating the ROI of Automation

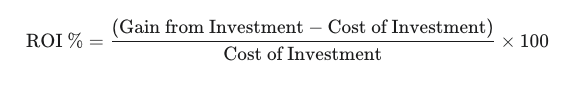

An investment in a WMS is not an expense; it's a measurable driver of profitability. While every business is different, you can estimate your potential return using a simple formula.

The ROI Formula:

How to Calculate Your Potential Gain:

Estimate your annual savings across these key areas:

- Reduced Labor Costs:

Time saved per order (picking, receiving, searching) x Hourly wage x Total annual orders - Cost of Errors Avoided:

Average cost per error (returns, shipping, replacement) x Number of errors per month x 12 - Increased Order Throughput:

Additional orders processed per day x Average profit per order x Operating days per year - Reduced Carrying Costs:

Value of excess inventory eliminated x Inventory carrying cost percentage (typically ~20%)

Cost of Investment includes the annual software subscription, any hardware (scanners), and initial training time. For most SMBs using a cloud-based WMS, the gains from just reducing picking errors and saving labor time often result in a positive ROI within the first year.

The Non-Negotiable WMS Feature Checklist

Demand these features from any system you consider:

- [✓] Real-Time Inventory Tracking

- [✓] Barcode & QR Code Functionality

- [✓] Address-Based Storage (Bin Location Control)

- [✓] Order Management Integration (e.g., Gincore)

- [✓] Reporting & Analytics

- [✓] Cloud-Based and Scalable

The Future is Automated (and Why You Can't Ignore It)

The trend towards smarter, more connected supply chains is accelerating. As leading analysts at firms like Gartner note, the future belongs to companies that leverage technology to enhance efficiency and visibility. For an SMB, a WMS is the foundational step into this more competitive landscape.

Every day you operate with a manual system is a day you choose to accept inefficiency. The right Warehouse Management System is designed to solve these exact challenges for SMBs, providing all the core automation features in a single, easy-to-use platform.

It’s time to take control of your warehouse.

Frequently Asked Questions (FAQ)

Will warehouse automation software replace my employees?

No, it empowers them. Automation handles tedious tasks, freeing your team to focus on higher-value activities like quality control, customer service, and process improvement.

We are a small business. Isn't a WMS too expensive?

Not anymore. Modern cloud-based WMS solutions are incredibly affordable, with subscription-based pricing that avoids a large upfront investment. The ROI often pays for the system within months.

How long does it take to implement a WMS?

A dedicated business can be up and running with a cloud-based system within a week, starting with core processes like receiving and picking before rolling out more advanced features.

Can a WMS integrate with my other software, like Shopify?

Yes, this is a critical feature. A good WMS should be your operational hub, integrating seamlessly with e-commerce platforms, marketplaces, and accounting software to ensure a single source of truth.

What is the very first step to getting started with warehouse automation?

The first step is to conduct a simple audit of your current processes. Identify your single biggest pain point. Is it picking errors? Slow receiving? Constant stockouts? Once you know your primary problem, you can evaluate WMS solutions based on how well they solve that specific issue.

.png)